Can A Composite Decking Kit Be Laid Directly On The Ground?

June 14, 2023

The Versatile World of Wood veneer for Interior and Exterior Walls

July 23, 2023

Revolutionizing Construction: The Next Generation of High-Strength Lightweight WPC Materials

Advancements in Composite Material Technology

As global demand for sustainable building solutions intensifies, wood-plastic composite (WPC) materials have emerged as a transformative force in construction and architectural design. These innovative composites artfully blend the organic appeal of natural wood with the engineered durability of polymer matrices, creating versatile materials that address critical industry challenges.

Challenges in Conventional WPC Formulations

Traditional WPC products, while offering notable advantages in termite resistance and moisture tolerance, have historically faced performance limitations:

- Compromised structural integrity from wood-plastic matrix imbalances

- Elevated density impacting installation efficiency

- Thermal expansion inconsistencies in variable climates

- Surface degradation from UV exposure and weathering

Breakthrough Material Architecture

The latest innovation in high-strength lightweight WPC materials features a sophisticated multi-layer structure engineered for optimal performance:

Advanced Composite Layering System

- Weather-Resistant Surface Layers

UV-stabilized polymer matrices enhanced with nano-scale inorganic particles provide exceptional weatherability - Structural Reinforcement Zone

Fiberglass-reinforced thermoplastic polymers create dimensional stability and load-bearing capacity - Lightweight Core Matrix

Proprietary blend of agricultural byproducts and mineral fillers achieves 20-30% weight reduction vs traditional WPC

Technical Superiority and Performance Benefits

This next-generation composite material delivers measurable improvements across key performance indicators:

- Flexural strength increased by 40-60% compared to conventional WPC

- Water absorption rates below 1.5% after 24-hour immersion

- Thermal expansion coefficient reduced to 0.8×10-5/°C

- Surface hardness reaching 85 HD on the Rockwell scale

Sustainable Manufacturing Innovations

The production process incorporates advanced eco-friendly technologies:

- Closed-loop material recycling system recovers 98% of processing waste

- Bio-based plasticizers replace traditional petroleum-derived additives

- Low-temperature extrusion process reduces energy consumption by 35%

Explore our sustainable manufacturing practices at plastory.com.

Diverse Application Scenarios

This advanced WPC material excels in numerous architectural applications:

Exterior Building Solutions

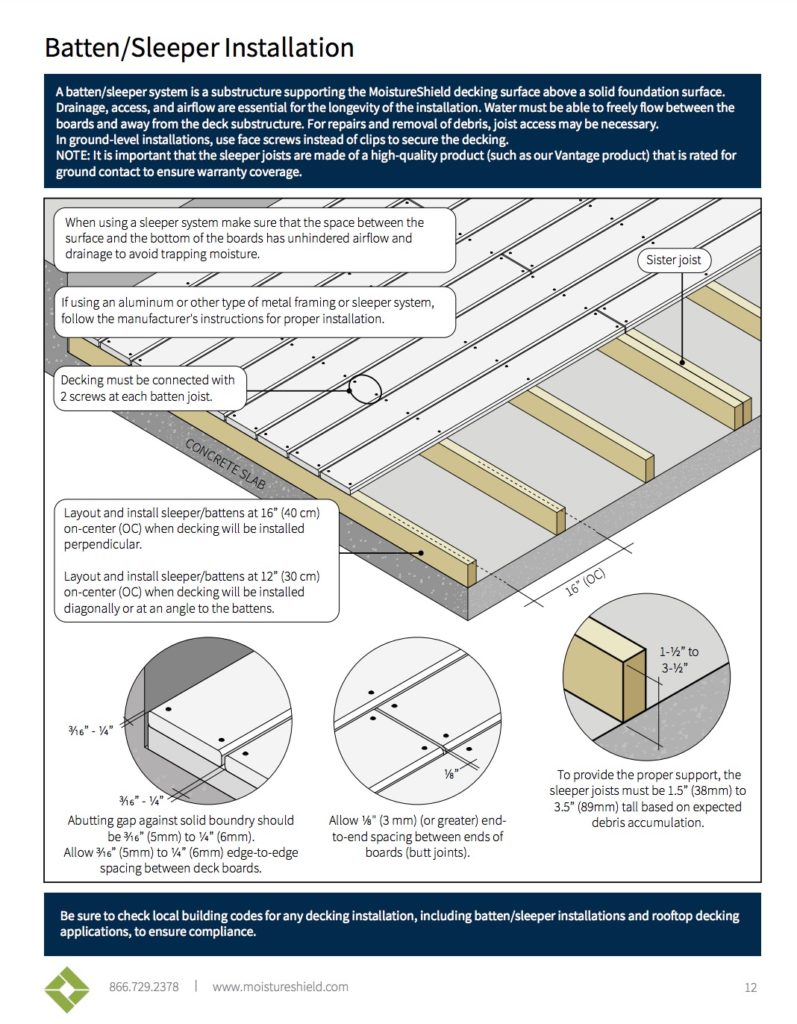

- High-performance decking systems with hidden fastener integration

- Weather-resistant façade cladding with integrated ventilation

- Structural landscaping elements for public spaces

Interior Design Applications

- Acoustically optimized wall paneling systems

- Moisture-resistant bathroom and kitchen installations

- Customizable decorative trim profiles

Comparative Advantages Over Traditional Materials

| Parameter | Traditional WPC | Advanced WPC |

|---|---|---|

| Density (g/cm³) | 1.25-1.40 | 0.95-1.10 |

| Impact Strength (kJ/m²) | 8-12 | 18-22 |

| Service Life (Years) | 15-20 | 25+ |

Future Development Directions

Ongoing research focuses on:

- Integration of self-healing surface technologies

- Development of fire-retardant formulations meeting UL94 V-0 standards

- Smart composite systems with embedded sensor technologies

For comprehensive technical specifications and application guidance, visit plastory.com.