Is WPC Decking Slippery? A Comprehensive Safety Evaluation

Surface traction remains a critical consideration in decking selection, particularly for exterior applications exposed to weather elements. As composite materials gain prominence in architectural applications, professionals and homeowners increasingly question: Does wood-plastic composite (WPC) decking provide adequate slip resistance? This technical analysis examines the anti-slip characteristics of WPC decking systems and their performance in wet conditions.

Technical Advantages of WPC Decking in Slip Prevention

1. Composite Material Engineering

WPC decking combines polymer matrices (typically HDPE or PVC) with wood flour in ratios optimized for surface friction. Unlike traditional timber that develops smooth patinas over time, the engineered composition maintains consistent micro-texture across its service life. This manufacturing process at industry-leading facilities ensures uniform surface characteristics critical for pedestrian safety.

2. Hydrophobic Surface Properties

Laboratory testing reveals WPC materials exhibit water absorption rates below 0.5% by volume, significantly outperforming pressure-treated lumber (≥20% absorption). This inherent moisture resistance prevents the surface lubricity common in water-saturated wood decking, maintaining Coefficient of Friction (COF) values above 0.6 in wet conditions – exceeding ADA recommendations for accessible routes.

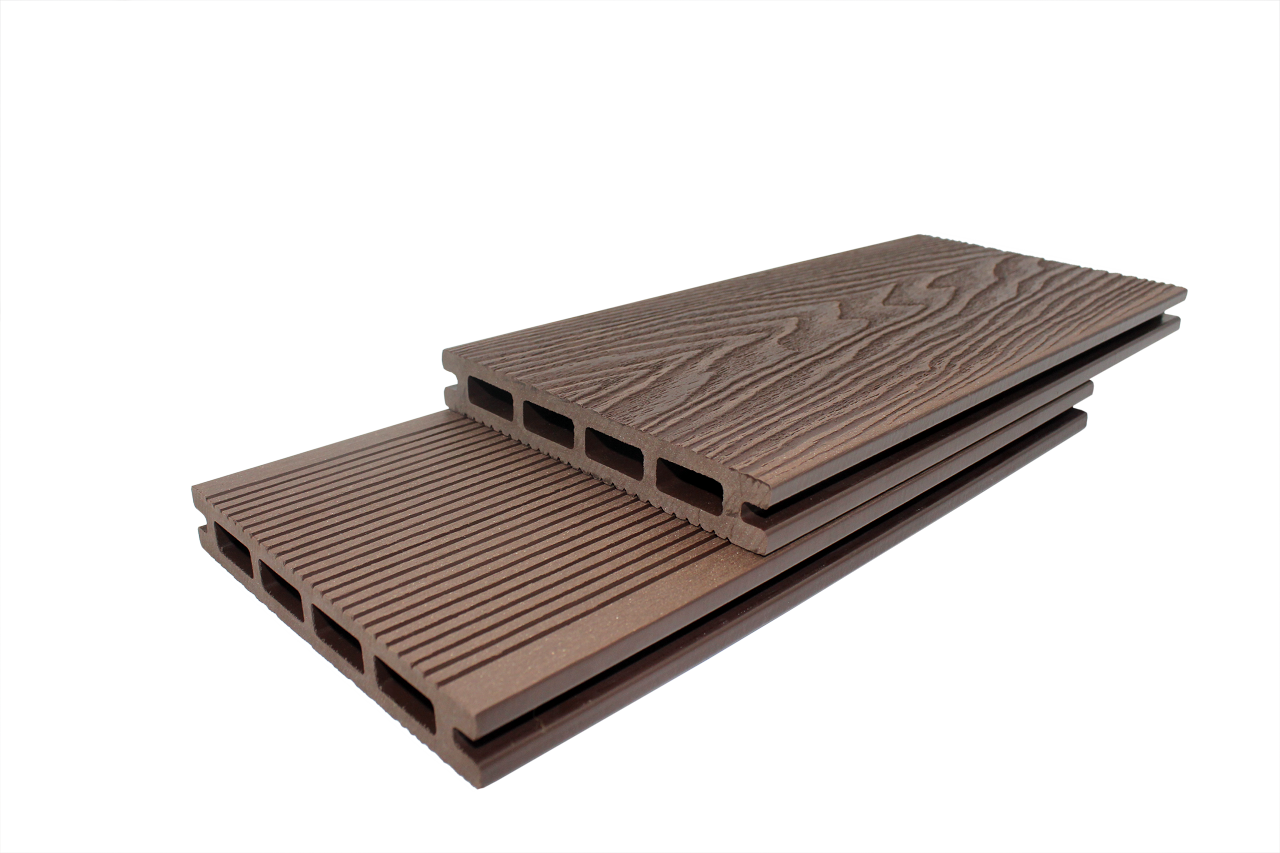

Figure 1: Surface profilometry analysis showing WPC decking’s anti-slip texture (Source: Plastory Materials Lab)

3. Enhanced Traction Design Features

Premium WPC products incorporate advanced texturing technologies:

- Embossed wood-grain patterns (Depth: 0.5-1.2mm)

- Directional micro-grooves for water channeling

- UV-stable polymer additives reducing surface glaze formation

Performance Comparison: WPC vs Traditional Decking Materials

| Material | Dry COF (ASTM D2047) | Wet COF | Maintenance Cycle |

|---|---|---|---|

| WPC Decking | 0.75-0.85 | 0.65-0.72 | Annual cleaning |

| Pressure-Treated Wood | 0.60-0.70 | 0.35-0.45 | Bi-annual sealing |

| Natural Stone | 0.50-0.60 | 0.25-0.35 | Quarterly cleaning |

Optimal Installation Practices for Maximum Slip Resistance

Proper installation significantly impacts WPC decking performance:

- Maintain 1/8″ gap between boards for thermal expansion

- Install with minimum 1% slope for water runoff

- Use corrosion-resistant fasteners from certified suppliers

- Implement perimeter drainage systems

Maintenance Protocol for Sustained Anti-Slip Performance

While WPC decking requires minimal upkeep, these practices ensure optimal safety:

- Bi-weekly sweeping with stiff-bristle broom

- Quarterly cleaning with pH-neutral detergent

- Annual inspection of drainage pathways

- Immediate removal of algal growth

Image 2: Proper installation techniques ensure maximum safety and durability (Credit: Plastory Installations)

Industry Certification and Compliance

Premium WPC decking systems meet rigorous safety standards:

- ASTM E303-93: Standard Test Method for Measuring Surface Frictional Properties

- EN 1339: Concrete paving slabs – Requirements and test methods

- ISO 10545-17: Ceramic tiles – Determination of coefficient of friction

Conclusion: WPC Decking as a Safety-First Solution

Through material innovation and intelligent design, modern WPC decking provides superior slip resistance compared to traditional decking materials. Its combination of moisture resistance, engineered texture, and durable composition makes it an ideal choice for pool surrounds, coastal properties, and commercial applications where safety is paramount. For architects and homeowners seeking certified non-slip solutions, Plastory’s WPC decking products offer third-party verified performance with 25-year limited warranties against slip resistance degradation.