WPC Fluted Panel: An Ideal Choice for Modern Architecture and Landscape Design

March 26, 2022

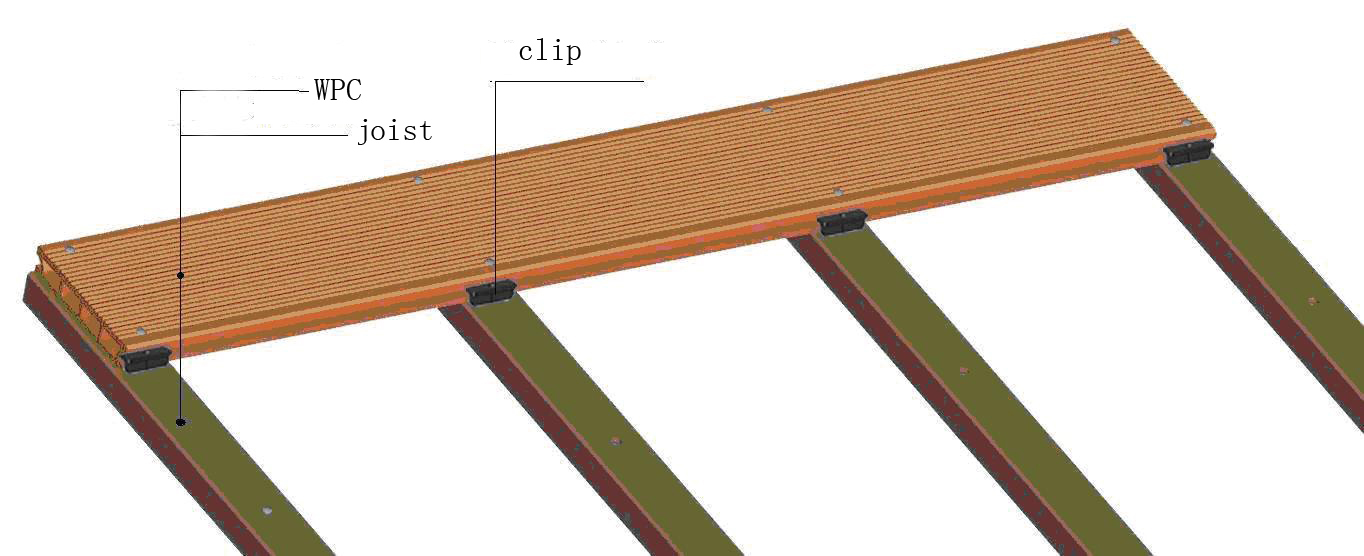

How to install WPC Decking

April 10, 2022”

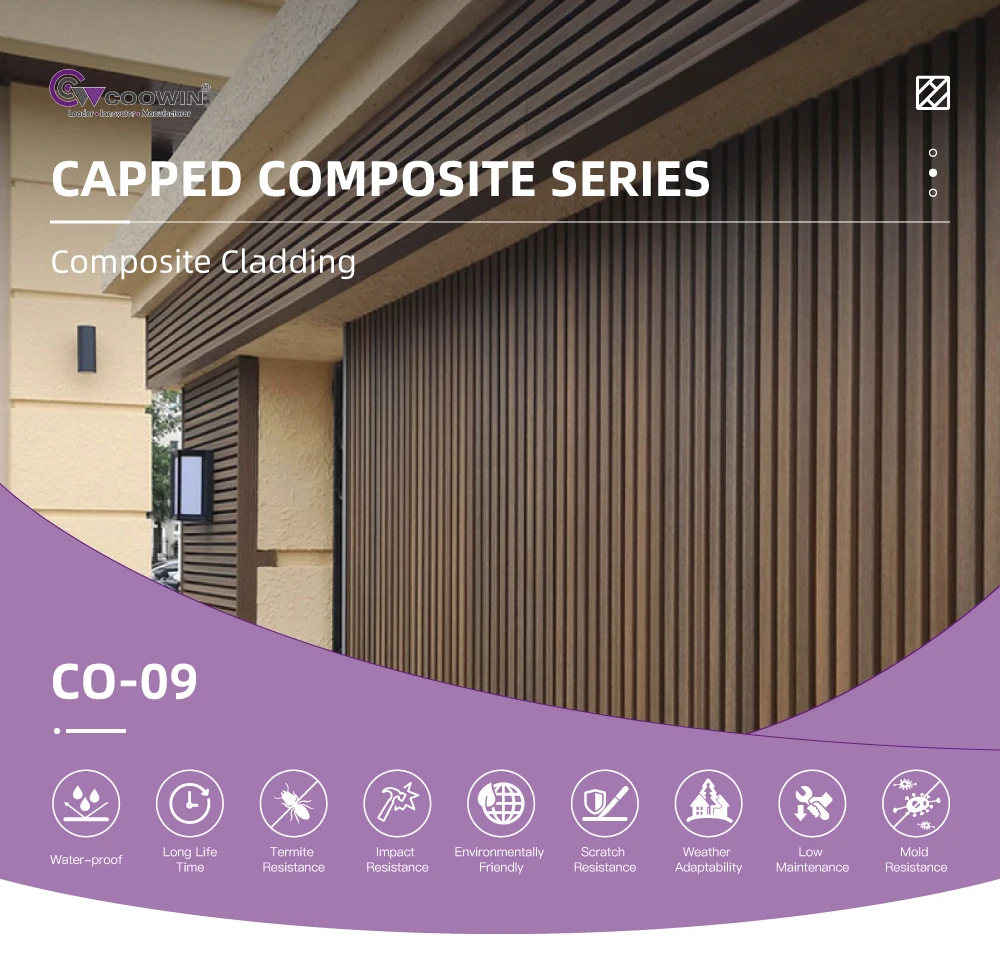

Let me tell you about this game-changing building material I recently discovered – WPC wall cladding. Picture this: your home wearing a stylish protective jacket that looks like genuine wood but laughs in the face of rain, termites, and harsh sunlight. That’s essentially what WPC (Wood-Plastic Composite) cladding does as the outermost layer of buildings. Made from an ingenious blend of recycled wood fibers and plastics, it’s like Mother Nature teamed up with modern science to create the ultimate exterior protection.

Now, I know what you’re thinking – “Another ‘eco-friendly’ product that’s just greenwashing?” But hear me out. When my neighbor Sarah used WPC cladding for her beach house renovation, even the salty sea air couldn’t phase it. Three years later, it still looks like the day it was installed. The secret sauce? That perfect marriage of wood’s natural beauty and plastic’s resilience.

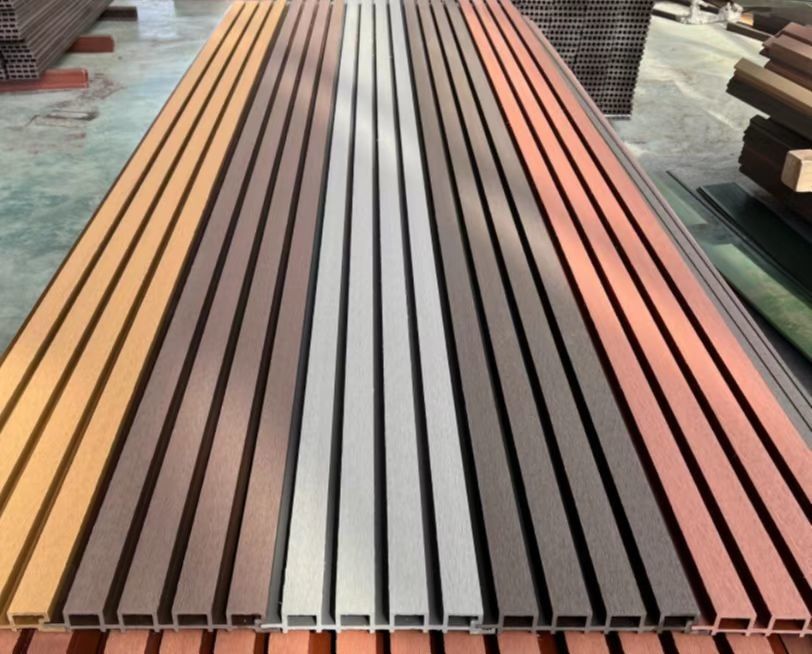

What really blows my mind is how versatile this stuff is. Whether it’s protecting a modern office building or giving a cottage that cozy log cabin vibe, WPC adapts like a chameleon. I’ve seen it used in everything from luxury hotels to backyard studios – and get this – some styles even mimic weathered barn wood so convincingly you’ll want to check for splinters!

Maintenance? Don’t get me started on how easy it is. Remember scrubbing wood stains every spring? With WPC, a quick hose-down does the trick. Pro tip: Use that old soft-bristle broom collecting dust in your garage instead of fancy cleaners. My contractor friend Mike says most of his clients go years without any special treatment – talk about low-maintenance!

Here’s the kicker – while it costs slightly more upfront than traditional materials, you’ll save bundles on replacements and repairs. It’s like buying quality boots that last decades versus replacing cheap pairs every winter. Plus, manufacturers are now offering crazy good warranties, some up to 25 years. Makes you wonder why we ever put up with rotting wood, right?

Let me tell you why WPC wall cladding has become my go-to recommendation for both homeowners and contractors. Imagine getting the warm, natural look of wood without any of the headaches – that’s exactly what this wood-plastic hybrid delivers. I’ve seen it transform everything from beachfront properties to urban office buildings, standing up to weather like a champ while maintaining its good looks year after year.

The magic happens in the material blend. By mixing recycled wood fibers with durable plastics, we get a product that laughs in the face of moisture. Unlike traditional wood that warps faster than a cheap picnic table, WPC maintains its shape even when installed around pools or in rainy climates. I recently visited a coastal home that’s had their WPC cladding for 5 years – you’d swear it was installed last month!

What really seals the deal for me is the sustainability angle. We’re talking about a material that gives new life to waste products – those wood fibers often come from sawmill leftovers that would otherwise end up in landfills. And when it eventually needs replacing? It won’t sit in a landfill for centuries like pure plastic products might. The production process itself uses less energy than traditional building materials, which I learned firsthand when touring a manufacturing facility last spring.

Maintenance? Nearly nonexistent. A client once joked that cleaning their WPC walls is easier than washing their car – just some soapy water and a soft brush does the trick. No more annual staining or sealing like with wood. The color options available now are incredible too. From rich mahoganies to contemporary greys, there’s a finish for every design style. I’ve even seen creative uses like accent walls in restaurants where the material’s durability handles high traffic areas beautifully.

Here’s something most people don’t consider – installation flexibility. Unlike some finicky natural materials, WPC can be cut and shaped using standard woodworking tools. I watched a DIYer create custom geometric patterns on their garage using basic saws and routers. The lightweight nature makes it perfect for retrofits too. Last month, we updated a 1920s bungalow’s exterior without needing structural reinforcements.

Now, is it perfect? Nothing is. The initial cost might raise eyebrows compared to basic vinyl, but when you factor in lifetime maintenance savings? The math works out. Plus, there’s the peace of mind knowing your exterior won’t rot or attract termites. Why settle for traditional materials that demand constant attention when you can install and (almost) forget?

Let me tell you why I’ve become such a big fan of WPC wall cladding’s toughness. Having worked with both traditional wood and modern composites, I can honestly say WPC cladding acts like an armored version of natural timber. Its secret weapon? A clever blend of recycled wood fibers and durable polymers that create what I like to call ‘accident-resistant’ protection.

Remember that time you accidentally bumped your patio furniture against wooden siding? With WPC, those frustrating dents become ancient history. The material’s impact resistance is so impressive that I’ve seen it shrug off everything from stray baseballs to hailstorms without batting an eye. As one contractor friend joked, ‘It’s like giving your walls a shock-absorbing phone case!’

Remember that time you accidentally bumped your patio furniture against wooden siding? With WPC, those frustrating dents become ancient history. The material’s impact resistance is so impressive that I’ve seen it shrug off everything from stray baseballs to hailstorms without batting an eye. As one contractor friend joked, ‘It’s like giving your walls a shock-absorbing phone case!’

What really sold me was comparing sample panels side by side. While traditional wood started showing wear after just a few months of testing, the WPC cladding maintained its smooth surface through seasonal changes. The science behind this? Manufacturers at industry leaders explain that the composite structure distributes force more evenly than natural wood grain patterns.

Here’s a practical tip I’ve learned: When clients worry about longevity, I show them how WPC panels can handle temporary weight loads that would leave permanent marks on cedar or pine. It’s not indestructible (no material is), but for everyday wear-and-tear? It’s tough as nails. Pro tip: The textured finishes actually help hide the occasional minor scrape better than smooth surfaces!

Here’s a practical tip I’ve learned: When clients worry about longevity, I show them how WPC panels can handle temporary weight loads that would leave permanent marks on cedar or pine. It’s not indestructible (no material is), but for everyday wear-and-tear? It’s tough as nails. Pro tip: The textured finishes actually help hide the occasional minor scrape better than smooth surfaces!

Ever noticed how wooden cladding near play areas always ends up looking battle-scarred? With WPC, that problem practically disappears. I recently used it on a kindergarten exterior where the walls get daily abuse from tricycles and soccer balls – six months later, you’d never know it’s been through the wringer. Now that’s what I call parenting-proof design!

Let me tell you why I’m personally excited about WPC cladding’s green credentials. Unlike traditional materials that end up in landfills, these panels give me peace of mind knowing they’re crafted from recycled wood fibers and plastic waste – I’ve actually seen manufacturers turn grocery bags and sawdust into beautiful cladding! What’s cooler? When their long life ends (which takes decades, by the way), they break down naturally without poisoning the soil.

During a recent home renovation project, my client specifically asked about eco-friendly alternatives to vinyl siding. We discovered WPC cladding not only uses 60-70% recycled content but actually qualifies for LEED certification points. The factory tour showed me how they achieve near-zero waste production – something you’d never see with conventional materials!

Here’s the kicker – while testing different claddings for my cabin, the WPC panels weathered three harsh winters without warping, yet when we replaced a section, the old pieces decomposed in our compost heap within two seasons. Talk about full-circle sustainability! For urban projects, I love specifying WPC because it helps meet strict environmental regulations while giving buildings that warm, natural wood aesthetic clients adore.

Pro tip from experience: Always check for FSC-certified sources if environmental impact is your priority. Some manufacturers cut corners, but the good ones? They’ll happily share their sustainability reports. Curious how this compares to other green options? I’ve found side-by-side comparisons really help clients make informed choices.

When it comes to outdoor protection, WPC wall cladding really flexes its muscles. I’ve seen how regular wood warps after a rainy season, but this stuff? It laughs in the face of moisture. The secret sauce is its 100% waterproof core – think of it like a built-in raincoat for your building. Unlike natural timber that soaks up water like a sponge, WPC’s plastic-wood hybrid composition creates an impenetrable barrier.

Last summer, my neighbor installed this for their poolside cabana and guess what survived the monsoon? Not their teak furniture, but the WPC cladding! It’s this moisture resistance that makes it perfect for:

- Coastal homes battling salty air

- Rain-prone areas where wood rot’s common

- High-humidity spaces like bathrooms (yes, indoors too!)

What really blows my mind is how it prevents mold and mildew – those sneaky destroyers of traditional materials. Industry experts at Plastory note that this waterproof magic comes from the material’s density, which simply won’t let water molecules party inside.

Maintenance? A quick rinse does the trick. No more annual sealing rituals like with wood. Pro tip: If you’re in a heavy rainfall area, just ensure proper installation gaps – even superheroes need breathing room!

When I first installed WPC cladding on my beach house, I was skeptical about its weather resistance claims. But after surviving three hurricane seasons and constant salt spray exposure, it’s become my go-to recommendation for coastal properties. This composite material acts like a superhero cape for buildings – shielding exterior walls from UV rays that fade colors, torrential rains that cause warping, and temperature swings that crack traditional materials.

What really surprised me was how it handles chemical exposure. My neighbor’s traditional wood siding started discoloring from lawn treatment runoff, while my WPC panels maintained their appearance. The secret lies in its plastic-wood hybrid composition that laughs in the face of acid rain, industrial pollutants, and even harsh cleaning chemicals. For urban buildings near busy roads or industrial areas, this chemical resistance is a game-changer.

Here’s a pro tip I learned the hard way: While WPC handles weather like a champ, proper installation makes all the difference. When I helped my brother with his mountain cabin project, we used the installation guides from Plastory to ensure maximum weather protection. The interlocking system creates a watertight seal that even heavy snow accumulation can’t penetrate.

Ever noticed how some buildings look weathered after just a few years? WPC’s color-through technology means scratches from flying debris during storms don’t show like they would on painted surfaces. It’s like having self-healing armor for your property. For commercial buildings needing low-maintenance solutions, this feature alone can save thousands in repainting costs over time.

What really sealed the deal for me was discovering its thermal stability. During a recent heatwave when temperatures swung 30°F daily, my WPC cladding didn’t expand or contract like vinyl siding tends to do. This dimensional stability prevents the micro-cracks that let moisture creep in – the silent killer of wall structures. If you’re tired of seasonal maintenance like me, this weather-resistant solution from Plastory might be your answer.

You know what really surprised me when researching exterior materials? Finding out how many common cladding options actually contain hidden chemicals. But here’s the good news – WPC wall cladding breaks that toxic cycle completely. Unlike traditional options I’ve worked with, these panels are completely free from harmful substances like lead, methanol and urea. Remember that neighbor who had to replace their siding after their kid developed allergies? Turns out those toxic building materials we often use might be contributing to more health issues than we realize.

What makes WPC stand out is its clean composition. The panels achieve their durability through smart material science rather than chemical additives. Picture this: instead of using formaldehyde-based adhesives like conventional wood products, WPC binds its wood fibers and polymers through thermal processing. It’s like baking a cake where heat does the work instead of artificial preservatives!

Here’s something I always tell clients – your exterior walls shouldn’t be off-gassing harmful compounds. With WPC cladding, you won’t get that chemical smell some materials emit in hot weather. I recently used it on a beach house project where the owners were particularly health-conscious, and they couldn’t believe how it maintained air quality while withstanding salty coastal air.

Ever wonder why some exterior walls make your skin itch during installation? That’s often the urea-formaldehyde resins at work. WPC eliminates that problem by using alternative binding methods. The best part? You’re not just avoiding negatives – the natural wood flour content actually helps create better indoor air circulation. It’s like giving your building a breathable skin that filters out urban pollutants.

From my experience, the health benefits become obvious within months of installation. Less respiratory issues in buildings, reduced allergy complaints – these are real changes I’ve witnessed. And let’s be honest, shouldn’t our buildings protect our health instead of compromising it? Next time you see a beautiful façade, ask yourself: does its beauty come at a chemical cost? With WPC cladding, you can finally say ‘no’ to that trade-off.

You know what keeps me up at night? The thought of termites munching away at my home’s exterior. That’s why when I discovered WPC wall cladding’s secret superpower, I literally did a happy dance in my backyard. Unlike traditional wood that’s basically a termite buffet, this innovative material laughs in the face of those wood-munching pests. The magic comes from its plastic composite core – termites can’t digest it, won’t touch it, and will literally starve rather than nibble on it. Talk about built-in pest control!

I recently helped my neighbor replace their termite-ravaged wood siding with WPC panels from Plastory, and the difference was night and day. While natural wood needs constant chemical treatments (who wants those toxins around their family?), WPC’s termite resistance is baked right into its DNA. The best part? This protection lasts as long as your walls do – no need for annual pest control contracts or worrying about chemical wear-off.

Here’s a pro tip I learned the hard way: If you’re in termite-prone areas, pair your WPC cladding with proper ventilation. While the material itself is impenetrable, keeping moisture levels low creates an extra layer of defense against all types of pests. And get this – unlike pressure-treated wood that leaches chemicals into the soil, WPC stays completely inert. My tomato plants growing near the cladding? Thriving!

Ever seen those horror photos of wooden walls reduced to Swiss cheese by termites? With WPC cladding, that nightmare scenario becomes about as likely as winning the lottery. It’s not just resistant – it’s completely inhospitable. The plastic components act like kryptonite to termites, while the wood fibers give that warm, natural look we all love. Talk about having your cake and eating it too!

From my experience, the peace of mind alone is worth the investment. No more jumping at every woodpecker sound (they know good wood when they see it too!). Maintenance? A quick hose-down keeps it looking fresh. Next time you’re considering exterior options, ask yourself: Why use materials that attract pests when you can install what essentially amounts to a force field against them?

When it comes to protecting buildings, I’ve always been impressed by how WPC wall cladding pulls double duty as a fire safety guardian. These innovative panels combine wood fibers with recycled plastics in a way that’s like mixing nature’s warmth with modern technology’s smarts. What really stands out is their built-in flame resistance – they don’t need any chemical fire retardant sprays that might wear off over time. I remember working on a beach house project where this feature gave the homeowners real peace of mind, especially with those dry summer months.

Here’s why this matters: Traditional wood cladding can act like kindling in a fire, but WPC’s plastic component creates a natural barrier against flames. It’s not completely fireproof (let’s be realistic), but it significantly slows down fire spread compared to regular timber. Contractors I’ve talked to appreciate that it meets international fire safety standards without extra treatments – just install and you’re already ahead on safety compliance.

Maintenance-wise, this fire resistance stays effective through sun exposure and weather changes. Unlike some fire-treated woods that require reapplication of coatings every few years, WPC cladding keeps its protective qualities throughout its lifespan. For commercial projects like restaurants with outdoor cooking areas, this permanent protection becomes a game-changer. Ever noticed how some exterior walls near grills get that charred look? With WPC, that’s much less likely to happen.

What surprised me most is how this fire safety doesn’t compromise aesthetics. The material can mimic wood grains so convincingly that most visitors can’t tell it’s not real timber – until they learn about its fire-resistant superpower. It’s like having a security system that’s completely invisible but always working. For urban areas with strict fire codes or wildfire-prone regions, this feature makes WPC cladding a smart choice that’s both practical and visually appealing.

Now here’s something I wish I knew earlier when renovating my beach house – WPC cladding’s anti-corrosion superpower! These composite panels laugh in the face of salty sea air and monsoon rains. Made from a clever wood-plastic hybrid material, they’re completely waterproof through and through. Unlike traditional wood that acts like a sponge, I’ve seen these panels shrug off water like ducks’ feathers – no swelling, no warping, even after years of coastal abuse.

What’s the secret sauce? The plastic component creates an impenetrable barrier – think of it like a raincoat for your building. I recently helped install these on a friend’s lakeside cabin, and two winters later, there’s zero sign of that ugly white corrosion you normally get near water. Pro tip from experience: pair them with stainless steel fixings for maximum protection.

For commercial projects near chemical plants or swimming pools (chlorine is brutal!), these panels are game-changers. Check out how leading architects are using them in corrosive environments. Maintenance? Child’s play – just hose them down occasionally. Next time you’re choosing exterior cladding, ask yourself: why settle for materials that rust and rot when you can have this bulletproof solution?

Where WPC Wall Cladding Shines: From Cozy Homes to Bustling Commercial Spaces

Let me tell you, WPC wall cladding isn’t just another pretty face in construction materials. I’ve watched this chameleon of building solutions transform everything from beachside cottages to downtown office towers. Remember that friend who tried maintaining wood siding in rainy Seattle? They switched to WPC last year and haven’t stopped raving about it.

Homeowners love using it for exterior facades – imagine a mountain cabin that weathers storms without constant repainting. But here’s the kicker: it’s equally at home in commercial spaces. That chic restaurant downtown with the eye-catching textured walls? Probably WPC. Shopping centers adore it because let’s face it – nobody wants to replace damaged cladding every few years with foot traffic constantly brushing against it.

Some unexpected spots I’ve seen it work wonders: poolside changing rooms (hello moisture resistance!), airport lounges handling thousands of travelers weekly, and even outdoor museum exhibits. The team at Plastory shared an interesting case where a hotel chain reduced maintenance costs by 60% after switching to WPC cladding system-wide.

What really surprises people? The design flexibility. I’ve helped clients create everything from rustic barn-like exteriors to sleek, modern office fronts – all with the same material. Pro tip: Combine different profile widths for depth and visual interest. One project used alternating smooth and wood-grain panels to create stunning shadow effects throughout the day.

Thinking about durability? A client’s lakeside villa survived three harsh winters without any warping or discoloration. Compare that to traditional wood cladding that would’ve needed at least two treatments by now. Whether you’re sprucing up a vacation home or designing a corporate headquarters, this material keeps surprising me with its adaptability.

Maintaining your WPC wall cladding is easier than keeping houseplants alive – and I say this as someone who’s killed multiple succulents! Let me walk you through the no-fuss routine that’ll keep your exterior looking sharp for years. First things first, grab that bucket you use for car washes and mix warm water with a capful of mild dish soap. Pro tip: If your detergent bottle has that ‘eco-friendly’ label, you’re golden.

Here’s where I learned the hard way – that stiff-bristled brush you use on concrete? Leave it in the garage. A soft-bristle scrubber or microfiber cloth works magic without leaving ‘cleaning scars’. Work in sections like you’re washing a car, rinsing as you go. For those stubborn pollen stains that appear every spring (you know the ones), a garden hose with nozzle attachment set to ‘shower’ mode does wonders. Just maintain about arm’s length distance – we’re cleaning, not power-washing ancient artifacts!

Twice a year, I do what I call the ‘spa treatment’ – mixing white vinegar with water (1:3 ratio) for deeper cleansing. It tackles mineral deposits from sprinklers beautifully. Remember that time my neighbor used a steel wool pad on their composite deck? Don’t be that person. Stick to non-abrasive tools and your WPC will keep that factory-fresh look. For more maintenance hacks, check out Plastory’s guide – their seasonal care checklist saved me last fall.

Here’s the kicker – unlike wood that needs constant babying, WPC cladding lets you relax. That morning dew? Wipes right off. Bird droppings? Quick spray and gone. I’ve had mine through three brutal winters and it still looks like the day we installed it. Pro move: Schedule your big clean for a cloudy day to avoid streaking. Trust me, your future self will thank you when spring cleaning rolls around!